FEATURES

Standard Grip Sheet tie sheets are available in basic paper weights from 60g/m2 to 300g/m2. In some applications, this just isn’t enough. ENDUPACK offers the Grip Pad for the most demanding applications.

Heavy water bottles are stacked on a pallet using a thick chipboard Grip Pad. Heavy water bottles are stacked on a pallet using a thick chipboard Grip Pad. |

Heavy weight rolls are being shipped on pallets doubled stacked using a Grip Pad between the two pallets Heavy weight rolls are being shipped on pallets doubled stacked using a Grip Pad between the two pallets |

Heavy weight rolls are being shipped on pallets doubled stacked using a Grip Pad between the two pallets Heavy weight rolls are being shipped on pallets doubled stacked using a Grip Pad between the two pallets |

Lightweight empty plastic bottles in plastic bags are being stacked 8 layers per pallets and 2 pallets high using Grip Pad for internal storage. Lightweight empty plastic bottles in plastic bags are being stacked 8 layers per pallets and 2 pallets high using Grip Pad for internal storage. |

BENEFITS

- Non-slip properties

- Very strong

- Reusable and recyclable

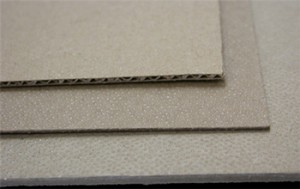

SPECIFICATIONS

On the top

e-flute corrugated board

0.075” (2 mm) thick

In the middle

Chipboard*

0.05” (1,3 mm) thick

Below

Chipboard*

0.160’’ (4 mm) thick

Grip Pad E-flute Corrugated Board Standard Stock Product

Sheet size : 47.25” X 39.4” (1200 mm X 1000 mm)

Available thicknesses: 0.075” (2 mm)

Grip Sheet non-slip coating: 100% 2 sides or alternate stripes

Material: medium et liners recyclés

Quantity per pallet: 500

Grip Pad Chipboard* 2 sides coated

Sheet size : Up to 60” X 120” (2,3 m X 4,6 m)

Available thicknesses: 0.05” to 0.165” (1,3 mm to 4,4 mm)

Grip Sheet non-slip coating: 100% 2 sides, waterproof finish available

Material: Dry finish chipboard 100% recycled

Quantity per pallet: As per specification

Grip Pad Chipboard* 1 side coated

Sheet size : Up to 60” X 120” (2,3 m X 4,6 m)

Available thicknesses: 0.085” to 0.16” (2,2 mm to 4 mm)

Grip Sheet non-slip coating: 100% 1 side, top or bottom, waterproof finish available

Material: Dry finish chipboard 100% recycled

Quantity per pallet: As per specification

* Chipboard versions of GripPad are made in Canada.

Documentation

Chipboard

GRIP PAD 1.2 GRIP PAD 3.0 PRODUCT SHEET

Corrugated board

E-FLUTEB-FLUTEBC-FLUTEPROD.SHEET