Endupack has been present on the market for non-slip waterproof paper used for the protection of palletized loads since 1987.

Through our 35 exclusive distributors we provide strategic stocks situated as close as possible to our customers and their markets.

Our business is 100% dedicated to the protection of Palletized loads, which means that we are able to work every day on improving and widening our offer in anticipation of the developments in our markets.

Products

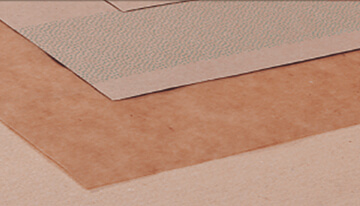

Grip Sheet separator sheet is used by numerous companies who care about the quality of their products and their pallets. Grip Sheet will preserve the homogeneity of your pallets from the palletization area to the filming area. ...

+

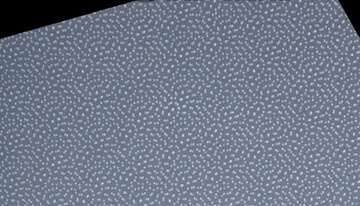

Square Grip is made from recycled paper and the coated portion is in equal squares (similar to a checkerboard) covering the surface on both sides. Advantages - low cost, high performance, great for automatic application. Available paper weights - 60g, 90g, 120g, 160g, 220g, 300g ...

+

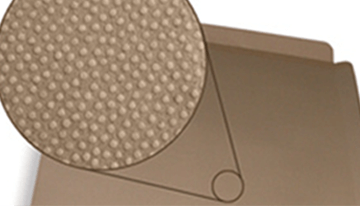

Clear Grip is made from polyester film, totally water proof, and even washable, and transparent. This is the ideal product for products requiring very clean standards. Advantages - Very high performance, waterproof and washable, transparent Available weights - 70gr/m2,105gr/m2.

...

+

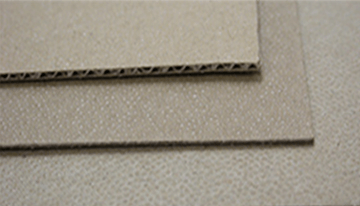

Slip sheets were first implemented by large food processors in the 70’s. It has now expanded int most industries and every mode of transportation.The increased usage of slip sheets is explained byits many advantages, not neglecting lower cost vs. the most widely ...

+

When you need strength... Standard Grip Sheet tie sheets are available in basic paper weights from 60g/m2 to 300g/m2. In some applications, this just isn’t enough. ENDUPACK offers the Grip Pad for the most demanding applications ...

+

Stop Gliss Origin has been the first non slide paper available as 1987. His unique technology and high non slide efficiency have been a reference in the market as a standard for the following non slide paper generations ...

+

Instead of stretch wrapping skids to go to the other end of the plant for finish work, we use Grip Sheets now, saving the time we use to spend running around the pallet. And we don't have to take the time to remove the film and rewrap it later. We also reuse the Grip Sheets a few times! They're saving us money in stretch film, and time, because they're so easy to use.

Arlington, VA, USA

We have these small boxes that were so unstable, we had to hand wrap them, because when we put them on the stretch wrapper turntable, they flew off. Now, with Grip Sheets, we don't need to bother with any hand wrapping, and can machine wrap all of our pallets with no down time.

Production Planner, Cosmetics, UK

Our poly wrapped trays of product don't have a lot of protection during shipment, so we want to be sure they are as secure as possible during transit. Grip Sheets let us rest assured that they will stay put, even on the roughest road.

Greeneville, TN USA

My boss was always telling me to find ways to go "GREEN" to help us meet our corporate goals. When I saw that Grip Sheets were made from recycled paper, and can be recycled, that got my attention. I'm glad we looked at them, because we now only do a top wrap of stretch film, so I really did find a way to go "GREEN.

Hamburg, Germany

We used to use a similar product on our automatic palletizer, but it did not have the alternating stripe pattern, and when we reached the bottom of the pallet, the sheets often stuck together, causing us a lot of headaches with downtime to clear the system. We don't have that problem with Grip Sheets.

Phenix City, AL USA